Facility Operation and Development (FOD) under the leadership of the Facility Design and Construction (FDC) Office and with support from a variety of contractors and outside engineering firms and in consultation with the Physics Department and others.

"AIR-

Naming the project improves communication and distinguishes it from other activities.

The three "Rs" denote Repair, Renovate, and Reconfigure. The University project designation

for this effort is OSU-

The project has been subdivided into two main phases. In concept, a third phase may follow dependent upon the results of the first two phases.

Many performance issues stemming from multiple root causes are present in the current systems. These issues have caused, among other things, premature deterioration of the machines to such a degree that an urgent need to halt this condition is now present.

The project seeks to remedy the underlying performance issues and to normalize the projected life span of the air handlers.

Phase 1: Creates a new air inlet north of the patio -

Phase 2: Focuses on AH-

on consecutive weekends in November. See project timeline for details.

Phase 3: Conceptual only. No design, schedule, or funding currently planned.

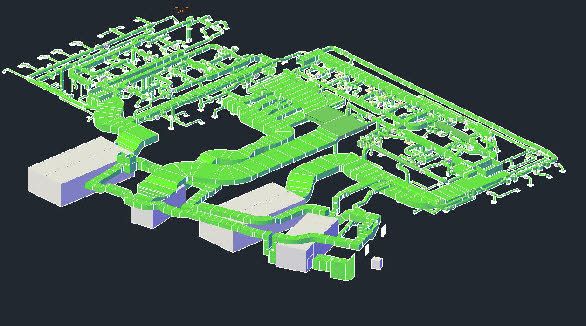

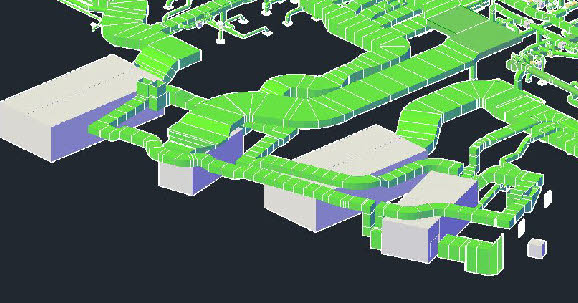

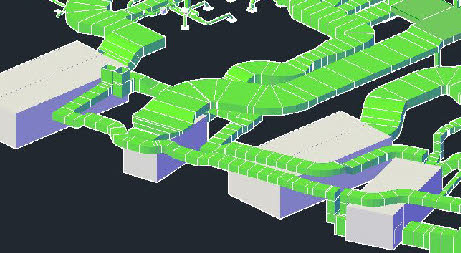

Phase 1 work was done in the main air inlet plenum and can be seen in completed form

near the north edge of the patio. Phase 2 will be work done within the internal space

of AH-

The project hopes to meet its goals by completing the following actions in the air

systems and/or within AH-

Phase 1: (completed)

-

Phase 2: (November 2013)

-

of softening salts into the air stream by installing a complete new system.

-

parts.

-

high-

-

air turning vanes with new aerodynamic profile turning vanes.

Total costs ~$900k split as Ph. 1 = ~$300k, Ph. 2 = ~$600k, Ph. 3 = $TBD (unfunded).

The funding is provided under the University/FOD Repair and Renovation (R+R) program.

Who:

What:

Why:

When:

Where:

How:

How Much:

Addition of a second source of outside air by digging an area well and connecting it to the existing plenum south of the major plenum obstructions.

Remove existing reheat coil, filter rack, and humidifier

Install high efficiency steam dispersion panels.

Install anti-

Install airfoil turning vanes (Aero-

Clean surface corrosion and paint with stabilizing paint

Replace complete main fan assemblies (2x)

Remove existing reheat coil, filter rack, and humidifier

Install a high efficiency steam dispersion panels.

Install anti-

Rework condensate trap; coat cooling coil pans to provide positive drainage.

Remove corrosion and restore interior surfaces by application of multi-

Additional insulation at southeast corner of main air plenum

Phase 1:

• Air Intake

Phase 2:

• AH-

• AH-

• Other

Completed in May 2013

3-

Outage 1 begins at close of business on Friday November 8th at 5:00 pm through start of business day Tuesday November 12th.

AH-

Fume hoods will be out of service during the full duration of Outage 1.

Focus will be on all mechanical assembly and demo work within both units.

2-

Outage 2 begins at close of business on Friday November 15th at 5:00 pm through start of business day on Monday November 18th

AH-

Fume hoods will be out of service during the full duration of Outage 2.

Focus will be on all corrosion removal and epoxy coating work within both units.

Phase 1:

Phase 2:

• Outage 1

• Outage 2

** Special Note

The Phase 2 dates presented above are now fixed. Effective 31-